Every gram of your insoluble API matters.

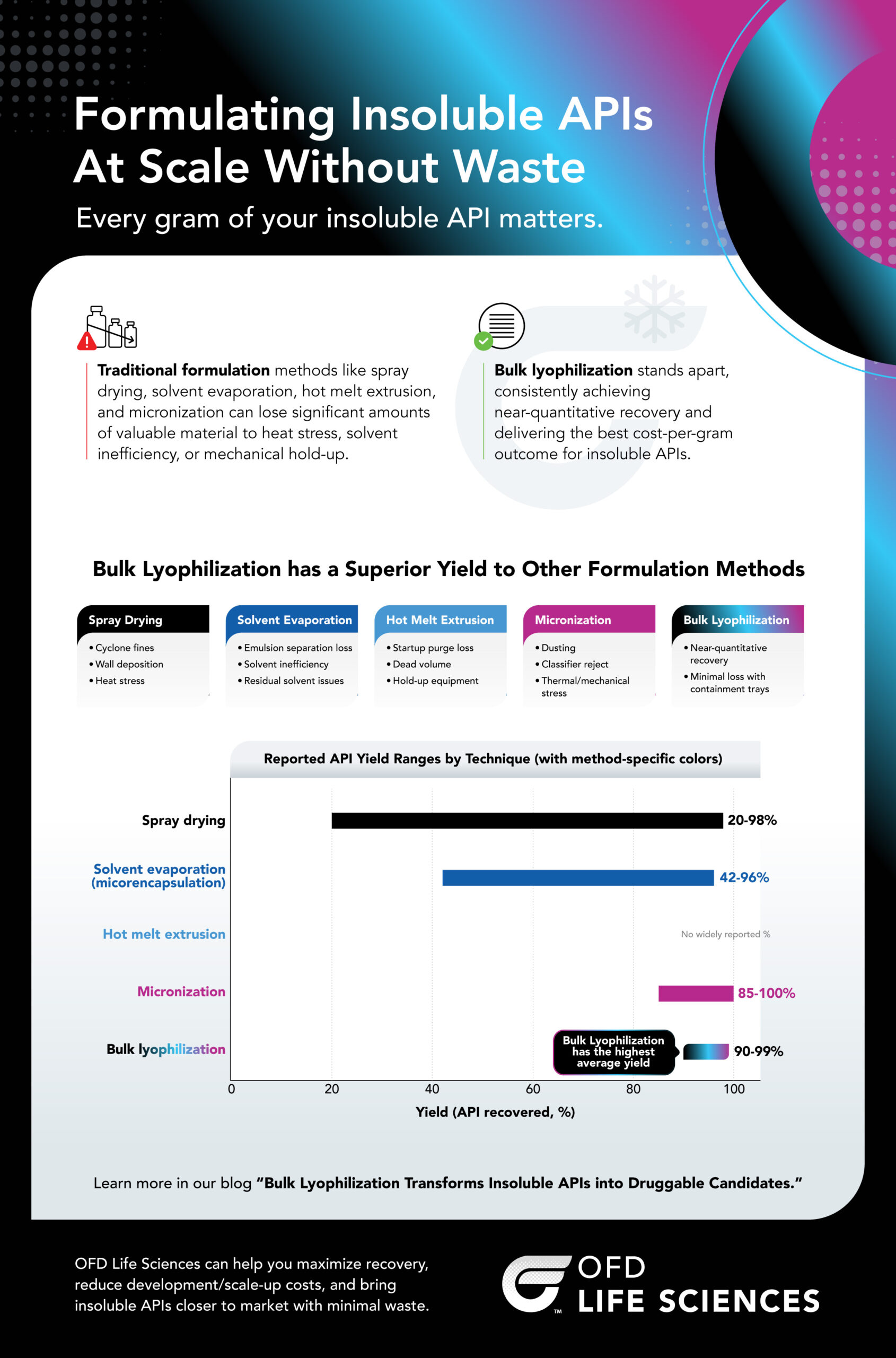

Traditional formulation method like spray drying, solvent evaporation, hot melt extrusion, and micronization can lose significant amounts of valuable material to heat stress, solvent inefficiency, or mechanical hold-up.

Bulk lyophilization stands apart, consistently achieving near-quantitative recovery and delivering the best cost-per-gram outcome for insoluble APIs.

Product Loss in Bulk Formulation

Reported API Yield Ranges by Technique

Spray Drying

• Cyclone fines

• Wall deposition

• Heat stress

API Yield Range: 20-98%

Solvent Evaporation

• Emulsion separation loss

• Solvent inefficiency

• Residual solvent issues

API Yield Range: 42-96%

Hot Melt Extrusion

• Startup purge loss

• Dead volume

• Hold-up equipment

API Yield Range: No widely reported %

Micronization

• Dusting

• Classifier reject

• Thermal/mechanical stress

API Yield Range: 85-100%

Bulk Lyophilization

• Near-quantitative recovery

• Minimal loss with containment trays

API Yield Range: 90-99%

Learn more in our blog “Bulk Lyophilization Transforms Insoluble APIs into Druggable Candidates.”