The Fragile Value of Botanical Extracts

Botanical extracts are a 6.91 billion dollar industry (and growing), prized for their diversity of bioactive compounds, from antioxidant-rich polyphenols to delicate aromatic oils. These natural molecules are what give botanicals their health-promoting power and their sensory appeal. But their value comes with a cost: they are remarkably unstable due to molecular volatility caused by exposure to heat and oxygen.

Turning an extract into a material suitable for downstream processing almost always requires a drying step, and the most common botanical extraction methods rely on heat to remove water. While efficient, these processes expose delicate compounds to stress conditions that can degrade potency. Heat, oxygen, and prolonged processing all accelerate the breakdown of antioxidants, flavonoids, and other sensitive molecules.

Studies on fruit juice and herbal extracts show significant losses of total phenolic content and antioxidant activity when using the spray drying formulation method at inlet temperatures of 170–180 °C (see figure below). Volatile aromatic compounds, which define the flavor and aroma of many botanicals, are also partially lost in hot drying gas streams.

For products that depend on consistency and efficacy, including those with a standard of identity or bioactivity claim, potency loss during formulation undermines both performance and trust.

For products that depend on consistency and efficacy, including those with a standard of identity or bioactivity claim, potency loss during formulation undermines both performance and trust.

While some botanical extraction methods succeed in preserving certain aspects of botanical quality better than others, only freeze-drying protects the full potency of an extract without compromise and at scale.

Spray drying is Most Commonly Used for Botanical Extracts

Spray drying is a formulation method that atomizes a liquid extract into a hot gas stream, water evaporates in seconds and a dry powder is collected. It is widely used for botanical extracts because it is fast, and economical at scale.

Spray drying is very well adapted to bulk production because it is capable of large volume lots and has large commercial equipment availability. However, high inlet temperatures can reduce phenolics and antioxidant activity, and volatile aromatics can be lost in the drying gas, which lowers potency compared with gentler methods.

Studies on maqui berry and other plant extracts report declines in total phenolics and antioxidant activity as inlet temperature rises into the 150 to 180 Celsius range.

Hot Air or Oven Drying Offers Accessible Formulation

Hot air or oven drying moves warm air across trays or belts until the target moisture is reached. It remains common for herbs and plant materials because the equipment is simple and accessible. This method can handle bulk plant matter on racks or belts, although uniformity and potency preservation can be challenging for sensitive extracts.

Despite this, long exposure to heat and oxygen can drive oxidation and browning, which often lowers phenolic content and antioxidant capacity relative to gentler methods. Recent work on culinary herbs and medicinal plants shows method-dependent changes in antioxidants and quality attributes, with oven conditions frequently underperforming freeze-drying on potency metrics.

Vacuum Oven Drying is Gentle on Small Batches

Vacuum oven drying removes water under reduced pressure, the lower boiling point allows drying at lower temperatures than ambient pressure. It is common for laboratories and small batches, and is sometimes used for heat-sensitive extracts that do not suit spray drying. Vacuum ovens are batch-based and therefore less efficient for very large bulk, which limits throughput compared with continuous systems.

Although gentler than hot air, vacuum oven drying still applies heat and can require long processing times, which can reduce certain bioactives depending on temperature and duration. Comparative studies on medicinal plants report that vacuum-based methods can outperform hot air on some potency measures, yet usually do not match freeze-drying for phenolic retention and antioxidant capacity.

Bulk lyophilization Retains Superior Potency During Formulation

Bulk lyophilization freezes the extract and then removes ice by sublimation under vacuum. This keeps product temperatures low and limits oxidative stress while water leaves the solid matrix.

A consistent pattern across many botanicals is stronger retention of phenolics and antioxidant capacity with lyophilization than with heat-based methods:

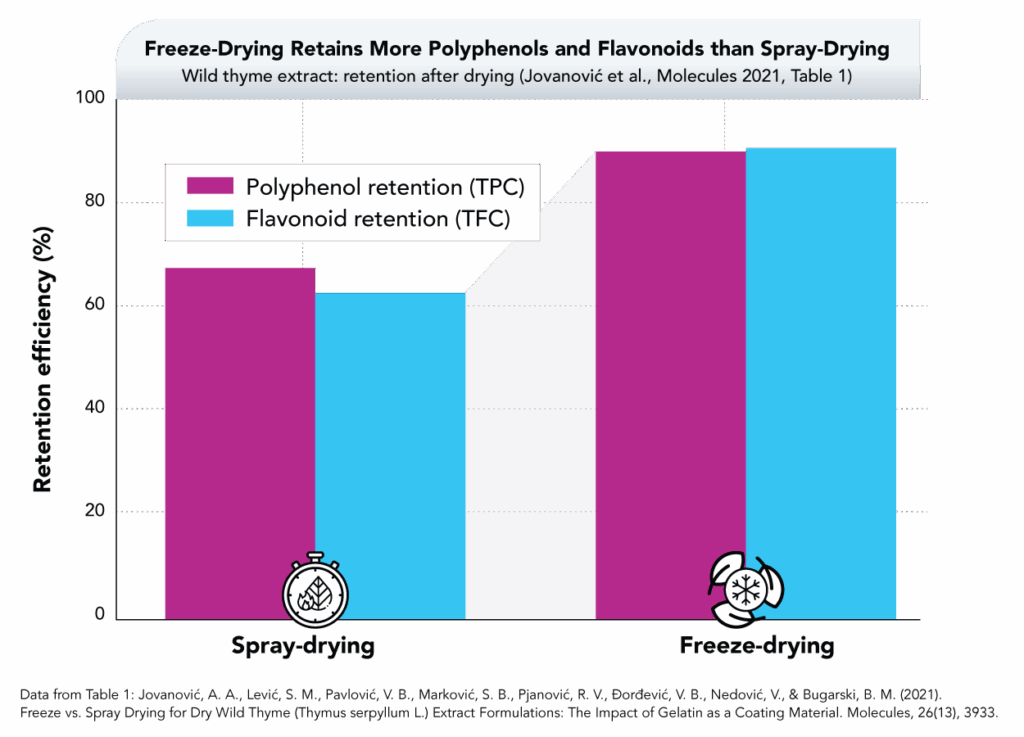

- In wild thyme, laboratory comparisons reported higher total polyphenols and total flavonoids for the lyophilized powders and a higher powder yield than the spray-dried powders.

- A study on fruits and medicinal plants also reports higher preservation of phenolics, color, and antioxidant activity with vacuum lyophilization than with hot air or vacuum-only methods, although the exact outcome depends on the matrix and the target compounds.

Bulk adaptation is straightforward because the product dries in trays rather than in final dose vials. Real-world comparisons also point to a yield benefit in bulk work because the material remains in trays, which reduces mechanical losses that are common in gas stream-based drying:

- The wild thyme study reported higher powder recovery for the lyophilized route than for the spray-dried route at laboratory scale.

When to Prefer Bulk Lyophilization in Botanical Formulation

- When the product’s label claim depends on phenolic profile, antioxidant capacity, or authentic aroma and color, which are sensitive to heat and oxygen.

- When batch-to-batch reproducibility and cycle transfer from development to production are critical for regulated or premium products.

- When recovery of scarce or high-value extract is a priority, and cyclone or baghouse losses would be unacceptable.

- When the formulation needs to be clean label and or minimal to retain larger concentrations that are complexed with dextrins.

Bulk lyophilization gives botanical formulators a reliable path to stable powders while keeping the molecules that matter intact. When potency is the differentiator, it is the most faithful route from extract to finished product. It produces a high-concentration, free-flowing powder that integrates smoothly into downstream dose forms. The bulk-lyophilized extract often supports higher dose loading per unit, subject to excipient and compressibility limits.

Bulk Lyophilization Also Excels in Formulating Other Product Types

If you are working beyond botanicals and want to know when bulk lyophilization makes sense for insoluble small molecules, probiotics, and advanced biologics, read the full white paper on the case for bulk lyophilization.